Purchase Order Processing - Appendix A - Purchase Order Replenishment

Inventory Item Maintenance/Stocking Information

Vendor Maintenance/Replenishment Parameters

Inventory Item Maintenance/Vendor Maintenance

Requisition Creation and Warehouse

Possible Reasons for an Item not Being Suggested for Replenishment

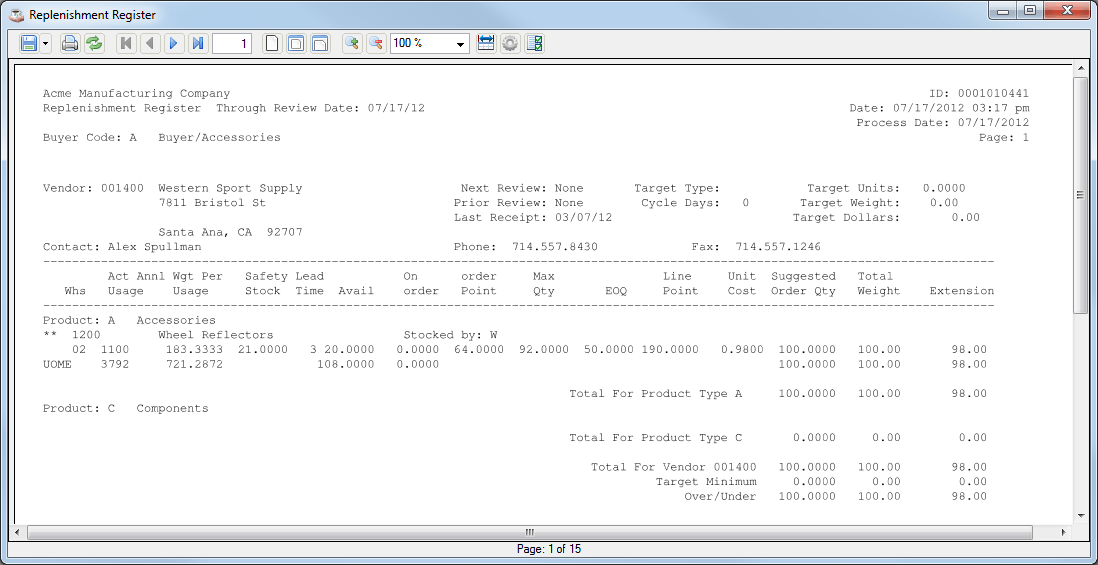

Replenishment Register

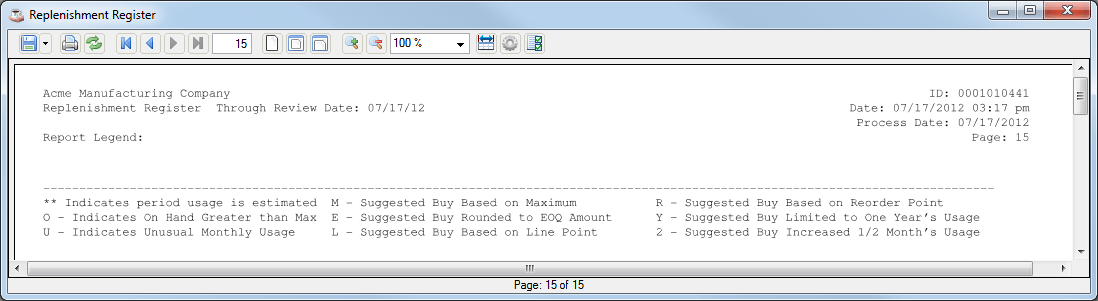

Adjustment Codes (return to top)

The following brief explanations of the adjustment codes, which are printed on the Replenishment Register, refer to fields that appear on the register. These fields usually come from the Item Maintenance Stocking Information task.

Replenishment Register code listing

|

** |

Indicates period usage is estimated |

Usage will be estimated when there’s not a full year's usage available. Remember that an estimated usage is also weighted according to the Parameter’s Inventory Factors. |

|

O |

Indicates On Hand greater than Max |

When On Hand is greater than Maximum Quantity, no order will be suggested. Note that in the case where Available plus On Order is greater than Line Point (which means that the item does not need replenishing) this ‘O’ code will not be printed even if the On Hand is greater than the Maximum Quantity. |

|

U |

Indicates unusual monthly usage |

The purpose of this code is merely to notify the buyer; it doesn’t affect the suggested buy calculation. This code is referring to the current month’s usage. Current usage is considered unusual when it is less than one half the average monthly usage for the last 12 months or greater than twice that average monthly usage. |

|

M |

Suggested Buy based on Max |

This is the normal state of affairs. Primarily, the suggested buy quantity will equal the Maximum Quantity minus the Available Qty minus the On Order Qty. This quantity will be rounded up to the nearest EOQ if EOQ is set. See the 'E' code below. |

|

E |

Suggested Buy rounded to EOQ amount |

As noted in the ‘M’ code explanation, the Suggested Order Quantity may be rounded up to the nearest EOQ. If this should happen, this code will be printed on the Replenishment Register. If EOQ is zero, the Suggested Order Quantity won’t be modified, and this code won’t be printed. An alternate time this code gets printed is when the Maximum Quantity is zero, and EOQ is not. In this case, Suggested Order Quantity is equal to the EOQ. |

|

L |

Suggested Buy based on Line Point |

When Maximum Quantity is zero and EOQ is zero, Suggested Order Quantity equals the Line Point. Line Point is a calculated value. It is Order Point plus Usage During Review Cycle. Order Point is a field entered in the Item Maintenance/Stocking Information task. Usage During Review Cycle is calculated based on the annual usage (which will be an estimated and weighted quantity when a full year’s usage history is not available) and the Cycle Days which come from either the Vendor Maintenance Replenishment Parameters Review Cycle Days field, or, if that field is zero, from the default Review Cycle Days field in Buyer Code Maintenance. |

|

R |

Suggested Buy based on Reorder Point |

When Maximum Quantity is zero and EOQ is zero and Line Point is zero, Suggested Order Quantity equals the Order Point. |

|

Y |

Suggested Buy limited to one year's usage |

When Maximum Quantity is zero, the quantity suggested is limited to one year's usage. If the Suggested Order Quantity needs to be adjusted to achieve this, the 'Y' code will be printed on the replenishment register. Of course this means that if one year's usage is zero, the quantity suggested will also be zero. No limit is applied to Suggested Order Quantities that are derived using the Maximum Quantity. It is assumed that the user will have a Maximum Quantity and an EOQ that have already taken this limit into account. |

|

2 |

Suggested Buy increased to 1/2 month's usage |

When Maximum Quantity is zero, any Suggested Order Quantity that is less than one half the estimated monthly usage will be increased to an estimated half month's usage. In this case, the '2' code will be printed on the replenishment register. As mentioned in the explanation of the 'Y' code, no limit is applied to Suggested Order Quantities that are derived using the Maximum Quantity. It is assumed that the user will have a Maximum Quantity and an EOQ that have already taken this limit into account. |

Inventory Item Maintenance/Stocking Information (return to top)

Clearly the values assigned in Inventory Item Maintenance/Stocking Information are crucial for the Replenishment tasks. The only two fields in the Stocking Information task which aren't somehow used to calculate the Suggested Order Quantity are Safety Stock and Lead Time. These two fields are printed on the Replenishment Register, but aren't used in a calculation since the user will have already incorporated them into the calculation of Order Point. EOQ, Order Point and Safety Stock can be manually maintained or optionally recalculated by the EOQ, Order Point & Safety Stock Report task, which is located on the Inventory Period End Processing Menu (IVP).

|

ABC Code |

Used to weight usage in cases where usage is estimated. |

|

Used in conjunction with Stocking Vendor to access Vendor Maintenance Replenishment Parameters Review Cycle Days (or Inventory Buyer Code Maintenance Review Cycle Days if vendor’s Cycle Days are zero). |

|

|

Stocking Vendor |

Used in conjunction with Buyer Code to access Vendor Maintenance Replenishment Stocking Vendor Parameters Review Cycle Days (or Inventory Buyer Code Maintenance Review Cycle Days if the vendor's Cycle Days are zero). |

|

Maximum Quantity |

Used directly in calculating Suggested Order Quantity. If Max is not zero, Suggested Order Quantity equals Max minus Available minus On Order all rounded up to the nearest EOQ. Clearly, this value must be meaningful and in keeping with desired reorder quantities. Adjust this quantity and the Review Cycle Days to achieve optimal replenishment quantities. |

|

Order Point |

Used in calculating Line Point which in turn is used as a point of comparison when determining if an item should be selected for replenishment. If an item's Available plus On Order is less than or equal to its Line Point, then it is eligible for replenishment. |

|

EOQ |

Used in calculating Suggested Order Quantity. Suggested Order Quantities derived from Maximum Quantity are rounded up to the nearest EOQ. Also, in cases where Maximum Quantity is zero, Suggested Order Quantity is equal to the EOQ itself. |

Vendor Maintenance/Replenishment Parameters (return to top)

Other fields important to the Replenishment tasks are found in Vendor Maintenance/Replenishment Parameters. Most of these fields are not actually used in determining replenishment quantities, but two of them are.

|

Purchasing Address |

Printed in the Vendor header. |

|

As already mentioned above, this field is important to replenishment calculations. It is used to calculate Usage During Review Cycle which in turn is part of the Line Point calculation. Remember that Line Point is used to determine whether an item is eligible for replenishment. The user figures and enters this value. Adjust this value and the Maximum Quantity to achieve optimal replenishment quantities. |

|

|

Next Review Date |

This field is also a vital part of Replenishment. This date is used to determine whether a buyer/vendor combination is eligible for the replenishment process. If this date does not fall within the date range entered into Replenishment Selection, items stocked by this buyer/vendor combination will be excluded from the results. This field is updated at the end of the Replenishment Register. |

|

Prior Review Date |

Printed in the Vendor header. This field is updated at the end of the Replenishment Register. |

|

Last Receipt Date |

Printed in the Vendor header. |

|

YTD Receipt $ |

Not currently used by the Replenishment tasks. |

|

YTD Receipt Weight |

Not currently used by the Replenishment tasks. |

|

YTD Receipt Units |

Not currently used by the Replenishment tasks. |

|

Purchase Target Type |

Printed in the Vendor header. |

|

Target $ |

Printed in the Vendor header and total. |

|

Target Weight |

Printed in the Vendor header and total. |

|

Target Units |

Printed in the Vendor header and total. |

Inventory Item Maintenance/Vendor Maintenance (return to top)

Some of the fields in Inventory Item Maintenance/Vendor Maintenance are used by the replenishment tasks. If a record exists here for the current stocking vendor being processed, the lead time reported on the register will be from the Lead Time field here. Also, the Quantity Discounts and Last Purchase Cost fields may be used in calculating the cost (see the Cost section below).

Selection Criteria (return to top)

The 'Through Review Date' dates that are printed after each inventory item in the register, warrant a special note. Consider the following example where the Replenishment Selection task is run two times:

|

Beginning Buyer |

Ending Buyer |

Beginning Vendor |

Ending Vendor |

Ending Date |

Comments |

|

C |

C |

000200 |

000200 |

10/30/12 |

Comment for the 1st selection |

|

C |

C |

000100 |

000300 |

10/15/12 |

Comment for the 2nd selection |

The buyer C/vendor 000200 combination is selected by both selection criteria. All inventory items listed on the register for the buyer C/vendor 000200 combination will have a 'Through Review Date' of 10/30/12 because it is the greatest Ending Date for the selection criteria that selected the buyer/vendor combination.

Cost (return to top)

Cost may be figured differently depending on how an item is stocked. This is because replenishment quantities for items stocked by warehouse are figured for each warehouse, while they're based on warehouse totals for items stocked by item. Regardless of stocking level, the cost will be from the Inventory Item Maintenance/Vendor Maintenance Quantity Discounts fields if they apply and are not zero. If there is no applicable quantity discount, the Last Purchase Cost from this same task is used. If the cost is zero in both of these places, a further cost calculation is made. What that calculation is depends on the stocking level of the item.

For items stocked by warehouse, cost comes from the unit cost in Inventory Item Maintenance/Warehouse Information. However, for items stocked by item, the cost is a weighted average based on the quantity on hand in each warehouse and the extension of that quantity times the unit cost for that item in that warehouse.

Referring to the following example, if the item is stocked at the item level, having the average unit cost be the total of the warehouse costs divided by the number of warehouses (i.e. 10*20/2 or 15) doesn't make common sense - not when we have 100 at $10 and only 1 at $20. The Replenishment Selection task will instead calculate the cost to be 10.099. It would arrive at this figure by adding Qty times Cost for each warehouse and dividing the result by the total Qty - specifically, ((100-10)+(1*20))/101.

|

Warehouse |

Quantity |

Cost |

|

01 |

100 |

$10 |

|

02 |

1 |

$20 |

|

Totals |

101 |

$30 |

Surplus (return to top)

For items stocked by warehouse, 'Surplus Other Whses' line may appear on the replenishment report. The 'other warehouses' shown may not be included in the selected warehouse range. Surplus is calculated as Available minus Line Point minus On Order.

Requisition Creation and Warehouse (return to top)

When a requisition is created for a suggested order, the fine items created need to have warehouses associated with them. If an item is stocked by warehouse, the warehouse used for the requisition line item is simply the one appearing on the replenishment report for that suggested item/warehouse. However, if an item is stocked by Item, the warehouse used in creating the requisition fine item will be the Default Warehouse as defined in Inventory Parameter Maintenance.

Possible Reasons for an Item not Being Suggested for Replenishment (return to top)

-

The Next Review Date (Vendor Maintenance Replenishment Parameters) for a vendor does not fall with in the specified date range.

-

Available plus On Order is greater than Line Point.

-

Available plus On Order is greater than Max.

-

The order point is 0, causing the item/warehouse to be skipped.

-

The Buyer Code assigned to the item in Inventory Item Maintenance Stocking Information task is not within specified Buyer range.

-

There is no Buyer Code assigned to the item in Inventory Item Maintenance Stocking Information task.

-

The Vendor assigned to the item in Inventory Item Maintenance Stocking Information task is not within specified Vendor range.

-

There is no Vendor assigned to the item in Inventory Item Maintenance Stocking Information task.

-

The warehouse associated with an item is not within specified Warehouse range.

-

No warehouse information exists for the item.

-

No stocking information exists for the item.

______________________________________________________________________________________

Copyright BASIS International Ltd. AddonSoftware® and Barista® Application Framework are registered trademarks.