Shop Floor Control - Pick List Printing

Function

Pick lists are used by warehouse personnel to collect and record material

being removed from stock and issued to a work

order![]() A document or group of documents that describes a job. A work order can also be a computer file that retains all job information.. As the stock is picked for a work order, warehouse

personnel record the number of units removed from stock. The completed

pick lists are then used as source documents for Work Order Issues. Pick lists

are created in the Release

A document or group of documents that describes a job. A work order can also be a computer file that retains all job information.. As the stock is picked for a work order, warehouse

personnel record the number of units removed from stock. The completed

pick lists are then used as source documents for Work Order Issues. Pick lists

are created in the Release![]() A process that converts a planned or quoted work order to the Open status. The process “releases” the job to the shop floor. It approves the work order for transactions and commits the materials to manufacturing process.

Work Order task portion of Work Order Entry when the checkbox for Print

Pick List is checked.

A process that converts a planned or quoted work order to the Open status. The process “releases” the job to the shop floor. It approves the work order for transactions and commits the materials to manufacturing process.

Work Order task portion of Work Order Entry when the checkbox for Print

Pick List is checked.

To access this task...

Select Pick List Printing from the Shop Floor Control main menu.

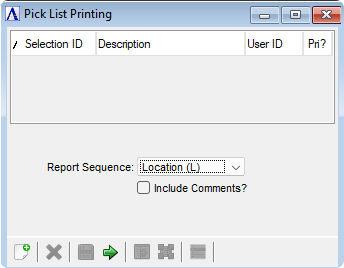

Pick List Printing

About the Fields

From the Report Sequence dropdown...

-

Location (L) to create a pick list with a location sequence.

-

Material (M) to create a pick list with a material sequence.

Include Comments? checkbox...

-

Mark the box to include WO Comments.

-

Unmark the box (default) to exclude WO Comments.

When finished making entries to the fields...

-

Click

to run the process.

to run the process. -

Click

to clear entries.

to clear entries.

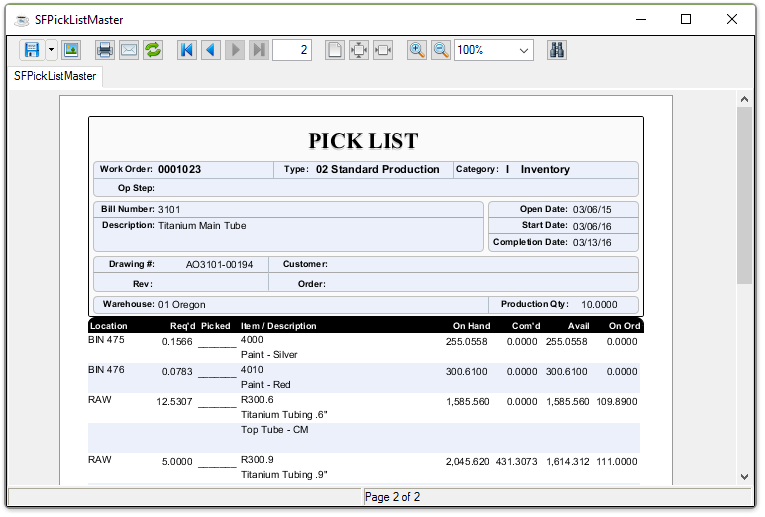

The resulting pick list is organized by bill number and sorted by operations steps either by location or material depending on the selections made in the report sequence step. The Work Order Pick List reports Committed and Available quantities that exclude the Required quantity that is to be picked for a component. This provides an easy evaluation of the quantities available to fill the immediate requirements. This means that the Available and Committed quantities displayed on the Pick List will not match those displayed on the Warehouse Master form and this is easily reconciled:

-

The committed quantity (the Com'd column) represents the Warehouse Master's Total Committed minus the component's required quantity (the Req'd column).

-

The available quantity (the Avail column) represents the Warehouse Master's Available plus the component's required quantity (the Req'd column).

Sample Pick List

See Output Options.

Update process completed.