Shop Floor Control - Materials Issues Entry

Function

Materials Issues Entry relieves inventory![]() The components, items, and raw material purchased or produced for resale or used to support production.

and creates a transaction

The components, items, and raw material purchased or produced for resale or used to support production.

and creates a transaction![]() The value added activity to the work order. Transactions include materials issues, labor and subcontract receipts.

in the work order

The value added activity to the work order. Transactions include materials issues, labor and subcontract receipts.

in the work order![]() A document or group of documents that describes a job. A work order can also be a computer file that retains all job information. field.

While materials issues will be generally generated from the materials

on the pick list

A document or group of documents that describes a job. A work order can also be a computer file that retains all job information. field.

While materials issues will be generally generated from the materials

on the pick list![]() A list of materials required for a job that is used to guide someone in the warehouse. In the context of shop floor, the Pick List allows for gathering the materials needed for each operation., you

can issue

A list of materials required for a job that is used to guide someone in the warehouse. In the context of shop floor, the Pick List allows for gathering the materials needed for each operation., you

can issue![]() To relieve on-hand inventories and charge those materials to a job. any

material to any open work order, regardless of whether the material

appears on the work order or the pick list, or whether it has been committed

to the work order.

To relieve on-hand inventories and charge those materials to a job. any

material to any open work order, regardless of whether the material

appears on the work order or the pick list, or whether it has been committed

to the work order.

To access this task...

Select Materials Issues Entry from the Transaction Processing menu.

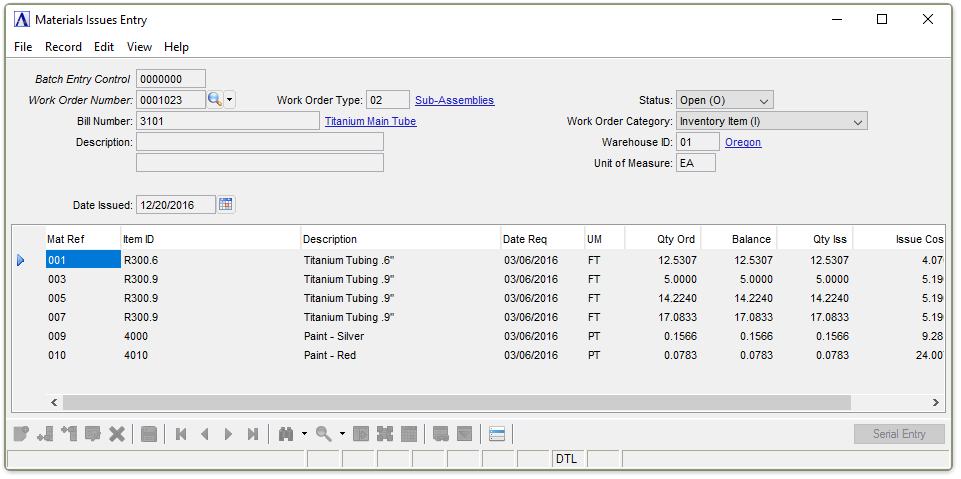

Materials Issues Entry

About the Fields

In the Work Order Number field...

-

Enter the work order number to issue materials.

-

Click

to select from a list of valid

work orders.

to select from a list of valid

work orders. -

Click the navigating buttons to view the address records;

to view the first record,

to view the first record,  to view the previous record,

to view the previous record,  to view the next record, and

to view the next record, and  to view the last record.

to view the last record. -

Click

to begin a new material issue entry.

to begin a new material issue entry.

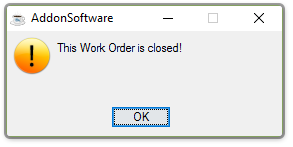

If a closed work order number is selected or entered, the system displays the prompt:

This Work Order is closed!

-

Press OK to access the Work Order Number field again.

In the Bill Number field...

Display only. Shows the number of the bill this work order will produce.

In the Description field...

Display only. Shows the description of the bill.

In the Date Issued field...

Display only. Shows the date of the previous issue.

In the Work Order Type field...

Display only. Shows the type of production used for creating the bill.

In the Status field...

Display only. Shows the status of the work order. Only open work orders can have materials issued.

-

Open (O)

-

Quote (Q)

-

Closed (C)

In the Work Order Category field...

Display only. Shows the category of the work order.

-

Inventory Item (I)

-

Non-Stock Item (N)

-

Recurring/Permanent (R)

In the Warehouse ID field...

Display only. Shows the warehouse from which the materials will be issued.

In the Unit of Measure field...

Display only.

Shows the

unit of measure![]() The unit of which an item is stocked or consumed. Examples are each, case, dozen, foot, etc..

The unit of which an item is stocked or consumed. Examples are each, case, dozen, foot, etc..

Entering Items to the Detail Lines

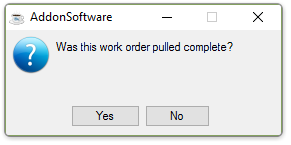

When issuing materials

for the first time, all items that entered in the Work Order Entry

task, or the items that are associated with the operation![]() A process in the production of an item, component, or finished good.

sequence that was selected, are listed after selecting Yes at the “Was

this work order pulled complete

A process in the production of an item, component, or finished good.

sequence that was selected, are listed after selecting Yes at the “Was

this work order pulled complete![]() A finished job. By contrast, work order can be partially closed. That is, a portion of the production is closed, but some still remains to be processed.?”

prompt, or after you enter a portion to be pulled. If a partial

issuance of materials has occurred in the past, these detail lines will

display only the remaining materials to be issued. As materials are completely

issued they are removed from the list.

A finished job. By contrast, work order can be partially closed. That is, a portion of the production is closed, but some still remains to be processed.?”

prompt, or after you enter a portion to be pulled. If a partial

issuance of materials has occurred in the past, these detail lines will

display only the remaining materials to be issued. As materials are completely

issued they are removed from the list.

Additional items may be added to this list. However, those items will not be updated to the work order and will only be effective for the current issuance. To make a lasting change to the work order it must be done in the Work Order Entry task.

Adding or Changing Materials Issues...

-

Click

to edit the form.

to edit the form. -

Click

to add an additional issue to

the list.

to add an additional issue to

the list. -

Click

to insert a new issue to the

list.

to insert a new issue to the

list. -

Click

to delete the entry.

to delete the entry.

Most of the following fields are displayed for existing items and are explained below for the entering of new items.

In the Mat Ref field...

Optional field. Enter a reference number such as a drawing number. This number will appear on the Closed Work Order Summary Register.

In the Item ID field...

-

Enter a valid item number code.

-

Click

to select from a list of valid

item codes.

to select from a list of valid

item codes.

When entering a lot/serial type inventory item, the Serial Entry button becomes active.

In the Description field...

Display only . A description of the item associated with the item ID is displayed.

In the Date Req field...

-

Enter the date that the item is required.

-

Press Tab or Enter to accept the default of today’s date.

In the UM field...

Display only . Displays the unit of measure.

In the Qty Ord field...

Display only. Shows the quantity of the item ordered on the work order.

In the Qty Iss field...

-

Enter the amount of material that was issued.

This field displays any amount that was issued. If the amount pulled for the order was different from the issue amount, an adjustment is made in this field when responding to the "Was this work order pulled complete?" prompt.

In the Issue Cost field...

Display only. Shows the cost of a single item.

When finished making entries to the fields...

-

Click

to save the records

to save the records -

Click

to begin a new work order entry.

to begin a new work order entry. -

Click

to delete the entry.

to delete the entry.

Detail lines previously accepted may only have changes made to the Date Required, UM, and Quantity Issued fields.

Was this work order pulled complete?

If the work order was pulled completely in its entirety, select Yes. The appropriate quantities issued are returned to the detail grid of the Material Issues Entry form.

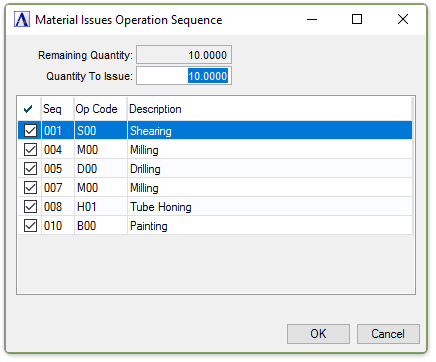

If the work order was not pulled complete, select No and the Material Issues Operation Sequence form displays to allow selecting or unselecting different operations and quantities may be adjusted.

Materials Issues Operation Sequence editor

When finished making entries to the fields...

-

Click OK to accept the changes.

-

Click Cancel to close the form without changes.

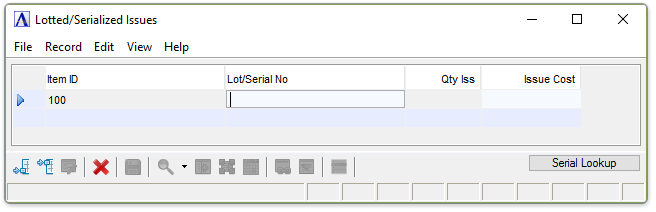

Lotted/Serialized Issues

When reviewing or adding an item that requires lot/serial numbers, the system will access additional lines for that entry. A serial/lot number must be assigned for each item issued.

If serial/lot numbers are not assigned, the update process during the Materials Issue Register task will not run.

The update removes inventory items from stock and issues them to the work order, thus creating work order transactions and applying material costs to the work order.

Lotted/Serialized Issues

Entering Serial/Lot Numbers

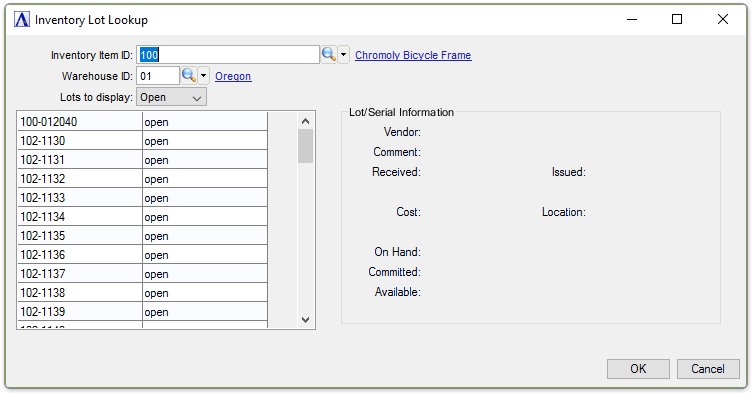

Select the Serial Lookup button to display the Inventory Lot Lookup window for the selected item.

Inventory Lot Lookup

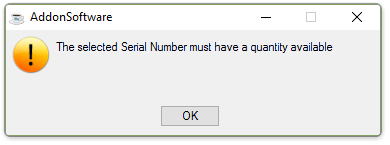

If the sum of serial/lot numbers assigned does not match the number of items issued, the system issues the prompt:

The selected Serial Number must have a quantity available

-

Click OK button and reselect another location from the Inventory Lot Lookup window.

Selecting a location with

quantity available![]() The quantity of materials available for use in production or sales. Available is calculated by subtracting Committed from On Hand. inserts

the location into the Lotted/Serialized Issues window.

The quantity of materials available for use in production or sales. Available is calculated by subtracting Committed from On Hand. inserts

the location into the Lotted/Serialized Issues window.

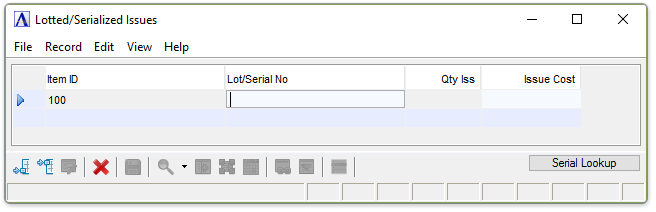

Lotted/Serialized Issues

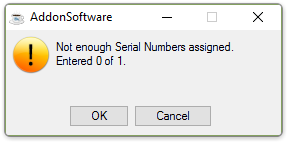

If insufficient quantities have been selected, the system displays the prompt:

Not enough Serial Numbers assigned.

-

Select the OK button and continue to make selections from available locations.

When finished making entries to the fields...

-

Click

to save the records.

to save the records. -

Click

to begin a new work order entry.

to begin a new work order entry. -

Click

to delete the entry.

to delete the entry.