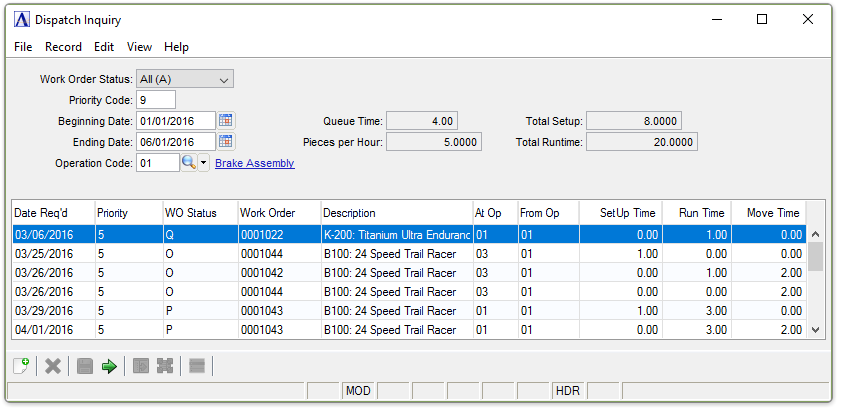

Shop Floor Control - Dispatch Inquiry

Function

The Dispatch![]() A document that lists all jobs to be worked on for the day, week or some period of time. AddonSoftware provides a dispatch inquiry as well as a report.

Inquiry enables a dispatch information view about each operation

A document that lists all jobs to be worked on for the day, week or some period of time. AddonSoftware provides a dispatch inquiry as well as a report.

Inquiry enables a dispatch information view about each operation![]() A process in the production of an item, component, or finished good. within work orders. It is

useful in helping determine which jobs need to be worked on. The date

and description of the operation, along with the setup, run, and move

times, are displayed. Each work order

A process in the production of an item, component, or finished good. within work orders. It is

useful in helping determine which jobs need to be worked on. The date

and description of the operation, along with the setup, run, and move

times, are displayed. Each work order![]() A document or group of documents that describes a job. A work order can also be a computer file that retains all job information.

that has the operation scheduled within the selected date range will be

displayed.

A document or group of documents that describes a job. A work order can also be a computer file that retains all job information.

that has the operation scheduled within the selected date range will be

displayed.

To access this task...

Select Dispatch Inquiry from the Shop Floor Control main menu.

Dispatch Inquiry

About the Fields

The type of information to display depends upon the selections made in these fields. Request information for an operation with the current date or within a selected range of dates.

From the Work Order Status dropdown...

-

All (A)

-

Planned (P)

-

Open (O)

-

Quote (Q)

In the Priority Code field...

-

Enter the minimum priority on a scale of 1 to 10 for viewing an operation code.

In the Beginning/Ending Date field...

-

Enter the first/last date for the inquiry.

-

Click

to use the tool to select the

date.

to use the tool to select the

date.

In the Operation Code field...

-

Enter a valid code of the operation to display.

-

Click

to select from a list of existing

operation codes.

to select from a list of existing

operation codes.

In the Queue Time field...

Display

only.Displays

the queue time![]() A record of the average amount of time material will wait in line for the next operation. established

in the Operation Code Maintenance task; or from the Bill of Materials

A record of the average amount of time material will wait in line for the next operation. established

in the Operation Code Maintenance task; or from the Bill of Materials![]() A listing of materials, operations, and subcontracts used to describe the manufacture of an item. Master File if installed.

A listing of materials, operations, and subcontracts used to describe the manufacture of an item. Master File if installed.

In the Pieces per Hour field...

Display only.Displays the pieces per hour established in the Operation Code Maintenance task; or from the Bill of Materials Master File if installed.

In the Total Setup field...

Display only.Displays the total setup established in the Operation Code Maintenance task; or from the Bill of Materials Master File if installed.

In the Total Runtime field...

Display only.Displays the total runtime established in the Operation Code Maintenance task; or from the Bill of Materials Master File if installed.

The following fields display and cannot be edited from this task:

In the Date Req’d field...

Displays the date that the operation is required.

In the Priority field...

Displays the priority code on a scale of 1 – 10. The default value is 5.

In the WO Status field...

Displays the status of the work order that contains the operation.

In the Work Order field...

Displays the work order number that contains the operation.

In the Description field...

Displays the item description in the operation.

In the At Op field...

Displays the operation the work order is currently running.

In the From Op field...

Displays the last operation applied to this work order.

In the Setup Time field...

Displays the amount of time used for setup.

In the Run Time field...

Displays the amount of actual processing time using Hours/Piece times Pieces/Hour times Production Quantity as the calculation.

In the Move Time field...

Displays the amount of time scheduled to move from one operation to the next.

When finished making entries to the fields...

- Click

to clear all selections.

to clear all selections. - Select

to

close the window.

to

close the window.