Shop Floor Control - Cost Variance Analysis Report

Function

Use this report to analyze

the difference between standard

and actual costs in operations, materials, and subcontracts. It is useful

in adjusting standard labor hours, tracking the performance of shop labor

and production management, and in analyzing the sources of labor variances.

A minimum variance![]() A comparison of actual cost (the total of all transactions) to the standards. Variances are negative when a job is exceeding the standards and are positive when it actually requires less than the standard. can

be selected and displayed and you have the option to only include those

items that involved a cost overrun.

A comparison of actual cost (the total of all transactions) to the standards. Variances are negative when a job is exceeding the standards and are positive when it actually requires less than the standard. can

be selected and displayed and you have the option to only include those

items that involved a cost overrun.

To access this task...

Select Cost Variance Analysis Report from the Reports menu.

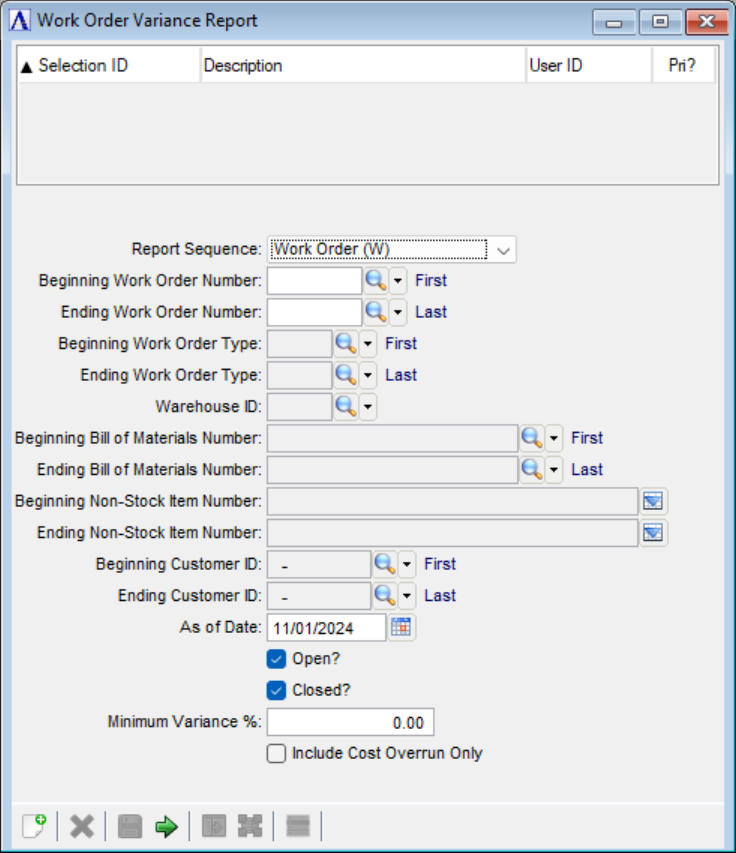

Cost Variance Analysis Report

About the Fields

From the Report Sequence dropdown...

-

Work Order (W) to sort the report by work order number.

-

Work Order Type (T) to sort by work order type.

-

Non-Stock Item (N) to sort the report by non-stock item number.

-

Bill Number to sort by bill number.

-

Customer ID to sort by customer number.

In the Beginning/Ending Work Order Number field...

This field is active when the Report Sequence Work Order (W) has been selected.

-

Enter the first/last number/code with which to begin the report.

-

Press Tab or Enter to use the first/last number available

The quantity of materials available for use in production or sales. Available is calculated by subtracting Committed from On Hand..

The quantity of materials available for use in production or sales. Available is calculated by subtracting Committed from On Hand..

-

Click

to select from a list of all valid

work order numbers.

to select from a list of all valid

work order numbers.

The requested information differs depending on what you entered in the Selected Report Sequence field. For Work Order, enter the lowest work order number that is to appear on the report. For Work Order Type, enter the lowest work order type code that is to appear on the report. For Customer ID, enter the lowest customer number that is to appear on the report. For Bill Number, enter the lowest item code that is to appear on the report. Numbers sort before letters.

In the Beginning/Ending Work Order Type field...

This field is active when the Report Sequence Work Order Type (T) has been selected.

-

Enter the first/last work order type code to begin the report.

-

Press Tab or Enter to use the first/last work order type.

-

Click

to select from a list of all

valid work order types.

to select from a list of all

valid work order types.

In the Warehouse ID field...

This field is active when the Report Sequence Bill Number has been selected.

-

Enter the warehouse ID for the report.

-

Click

to select from a list of all valid warehouse IDs.

to select from a list of all valid warehouse IDs.

In the Beginning/Ending Bill of Materials Number field...

This field is active when the Report Sequence Bill Number has been selected.

-

Enter the first/last bill of materials

A listing of materials, operations, and subcontracts used to describe the manufacture of an item. number to begin the report.

A listing of materials, operations, and subcontracts used to describe the manufacture of an item. number to begin the report.

-

Select theTab or Enter keys to use the first/last bill of materials record.

-

Click

to select from a list of all valid bill of material numbers.

to select from a list of all valid bill of material numbers.

In the Beginning/Ending Non-Stock Item Number field...

-

Enter the first/last non-stock item number to begin/end the report.

-

Leave field blank to use the first/last non-stock item number.

-

Click [image] to select from a list of non-stock items for current work orders.

In the Beginning/Ending Customer ID field...

This field is active when the Report Sequence Customer ID has been selected.

-

Enter the first/last customer ID to begin the report.

-

Select theTab or Enter keys to use the first/last customer ID record.

-

Click

to select from a list of all valid customer ID records.

to select from a list of all valid customer ID records.

In the As of Date field...

-

Enter the closing date to calculate cost variances.

-

Clear the field to include all dates.

-

Click

to use the tool to select the date.

to use the tool to select the date.The report will calculate the variance in the work orders as of the date entered at this prompt.

Checkboxes...

Select any combination of the following:

-

Mark Open? to create a report for open work orders.

-

Mark Closed? to create a report for closed work orders.

In the Minimum Variance % field...

-

Enter the minimum variance percent to report. The percentage entered represents the amount over or under cost allowed. Anything outside of these criteria will be included in the report.

Include Cost Overrun Only checkbox...

-

Mark the box to select only positive variances.

-

Unmark the box to select positive and negative variances.

When finished making entries to the fields...

-

Click

to save the selections.

to save the selections. -

Click

to clear the form and begin again.

to clear the form and begin again. -

Click

to

run the report.

to

run the report.

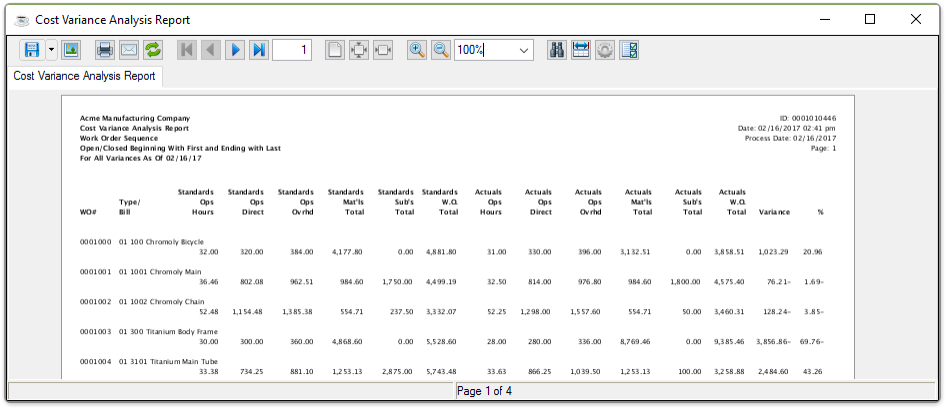

Sample Cost Variance Analysis Report

See Output Options.