Shop Floor Control - Bottleneck Analysis Report

Function

Use this report to determine

where scheduled production will cause a bottleneck![]() An operation that is scheduled for more labor hours than that resource has the capacity to complete. A resource that has demand that exceeds capacity is considered to be a bottleneck..

Base the report on whatever utilization is necessary and run it for only

certain operations and through a set range of dates. A resource

that has demand that exceeds capacity is considered to be a bottleneck.

The estimated starting date, actual start, and estimated completion dates are shown, along with

the date required.

An operation that is scheduled for more labor hours than that resource has the capacity to complete. A resource that has demand that exceeds capacity is considered to be a bottleneck..

Base the report on whatever utilization is necessary and run it for only

certain operations and through a set range of dates. A resource

that has demand that exceeds capacity is considered to be a bottleneck.

The estimated starting date, actual start, and estimated completion dates are shown, along with

the date required.

To access this task...

Select Bottleneck Analysis Report from the Reports menu.

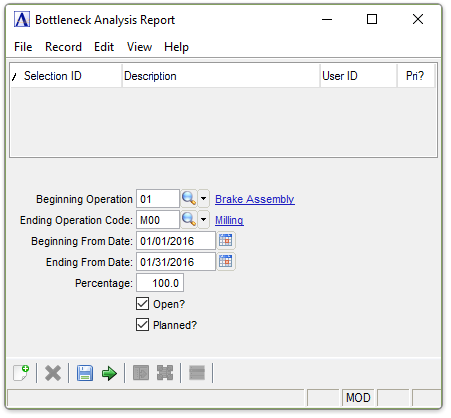

Bottleneck Analysis Report

About the Fields

In the Beginning/Ending Operation Code field...

-

Enter a valid operation

A process in the production of an item, component, or finished good. code.

A process in the production of an item, component, or finished good. code.

-

Select TaborEnter to use the first/last operation code on record.

-

Click

to select from a list of all valid operation codes.

to select from a list of all valid operation codes.

In the Beginning/Ending From Date field...

-

Enter the first/last date for the report.

-

Select Tab or Enter to use the first/last date of operations.

-

Click

to use the tool to select the date.

to use the tool to select the date.

In the Percentage field...

Enter the minimum percent of utilization to report.Any operation that is scheduled beyond this utilization will be considered a bottleneck.

Open? checkbox...

-

Mark the box to include open work orders.

-

Unmark the box to exclude open work orders.

Planned? checkbox...

-

Mark the box to include planned work orders.

-

Unmark the box to exclude planned work orders.

When finished making entries to the fields...

- Click

to save the selections.

to save the selections. -

Click

to clear the form and begin again.

to clear the form and begin again. -

Click

to run the report.

to run the report.

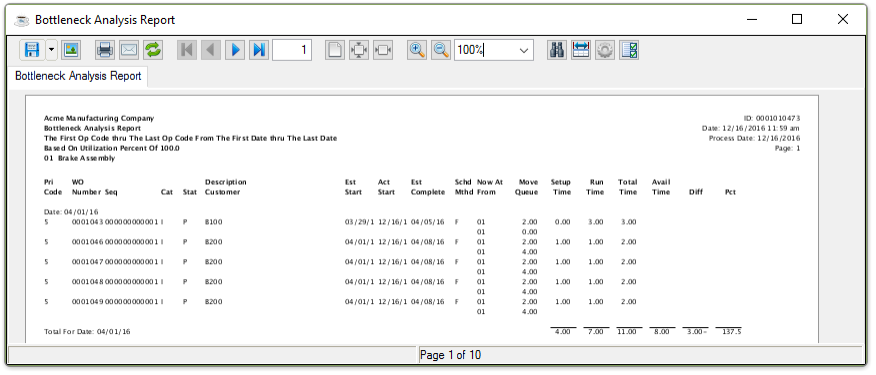

Sample Bottleneck Analysis Report

See Output Options.